Concrete Mix Design Submittal Procedure

SUBMITTAL PROCEDURE

- Details

GENERAL INFORMATION:

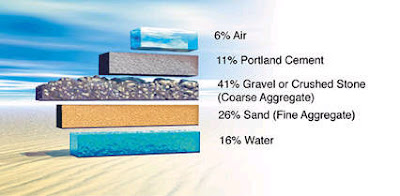

All materials proposed for use in concrete and all concrete mix designs shall be approved by the Client prior to use. Such materials include coarse and fine aggregates, cementitious materials, admixtures and water. All materials shall be SAMPLED and TESTED after December 1st of the previous year or the most current testing data if ANNUALLY tested by MOC.

All Client's approved mix designs for 2017-2018 will expire on December 31, 2018, even if mixes are used on multi-year construction projects. New mix designs must be submitted to CASPAR to remain an approved MOC supplier for 2019. Mix designs, meeting specification requirements, in PDF format, received by December 15, 2018 will be approved by the deadline.

MOC will preapprove aggregates and cementitious materials. Submit certifications directly to MOC. If the material is approved by MOC it will be added to the website as an option.

FEES:

Concrete Materials:

PKR 5000 fee per material

Concrete Mix Designs:

PKR 10000 fee per mix design when received before December 15, 2018

PKR 12000 fee per mix design when received after December 15, 2018

PKR 24000 fee per mix design requiring approval in less than 10 working days received at anytimeNote: An additional PKR 12000 fee will be assessed for each mix design requiring a second round of comments and PKR 12000 for any additional round of comments.

CASPAR will invoice for all concrete material and all concrete mix design submittals. Please do not submit payment prior to receiving an invoice. Please make all checks payable to CASPAR.

All mix designs shall be submitted through the website using the current Mix Design Submittal Form on www.casparassociates.com.

Strength tests will be the first item reviewed in any submittal.

Mix designs with incomplete or incorrect strength tests will be returned without further review of the mix design. This will count as the first round of comments.

All mix designs are good for one year and must follow the current MOC Concrete Material Specification.

SUBMITTAL REQUIREMENTS:

Concrete mix design submittals shall include:

- Completed “Mix Design Submittal Form” with attached supporting documentation (strength tests, material certifications and admixture data sheets).

- Proportion of admixtures (Admixtures for water reduction, set acceleration, set retardation, or viscosity modifiers may be shown as optional. Provide addition rate ranges and specific dosage rates for ALL admixtures in the mix design. ALL optional admixtures shall be submitted in the following format for dosage: zero, anticipated dosage, approved range (0, X (Y-Z) cwt. Admixtures listed as optional shall require approval from the owner prior to use.

- Admixtures shall be on the Ministry of Communication.

- Admixture submittals shall include documentation from the manufacturer which provides addition rates. If addition rates for admixtures do not fall within the manufacturers recommended dosage rate, as listed in supplied documentation, a letter from the manufacturer shall be provided. The letter shall specifically state the dosage rate and range approved by MOC. Individual members reserve the right to reject mixes with admixtures falling outside the manufacturers recommended dosage rates.

- Documentation of average compressive strength:

A minimum of three compressive strength tests shall be performed by a qualified laboratory. A strength test is defined in Article 26.12.1.1 of ACI 318-14. Test strengths shall meet or exceed the required average strength as shown below.

Compressive strength test results (strength tests) are required for each mix design submitted. However, if mix designs differ only in water to cement ratio, compressive strength test results for the highest water cement ratio will be acceptable in all mix designs of the series. Strength tests shall be on concrete that contains materials, sources, ratios, admixtures and admixture dosages consistent with the submitted mix design and shall meet the current specification requirements. For currently approved mix designs, each strength test shall have been completed after the most recent approval date (except as noted below). For new mix designs, strength tests shall have been completed within the previous 12 months.

An example of an acceptable test is as follows:

- Batch three separate truckloads of concrete mix design at the same water/cement ratio

- Cast three 4-inch cylinders for each batch and break at 28 days

- Submit test results for each 3-cylinder set

- Submit batching information for each set

- Average of strength tests must equal or exceed 1200psi + design strength

Please contact the MOC administrator prior to casting cylinders if you have any questions.

Each strength test shall represent concrete from separate batches that include all the water, cement, and non-optional admixtures in the design. The following shall be provided with each strength test:

- Batch tickets or laboratory data including: plant name, design w/c ratio, design weights per cubic yard, total weight of all materials batched, time batched, design slump, moisture correction for aggregates, and dosages of all admixtures. Batch tickets or laboratory data shall be easily correlated with strength test results.

- Documentation for each batch showing how the water/cement ratio was calculated (for example: portland cement, water added at the plant, free water on aggregate, water added on site). Include any other supporting documents. Strength tests, submitted for annual approval, on concrete with water/cement ratios below design are not acceptable. Batch tickets or laboratory data showing unapproved additions to the concrete will not be accepted.

The average of the strength tests shall meet or exceed the required average compressive strength as determined by ACI 301-16, Article 4.2.3, with the following modification:

At least one half of the tests used to determine the standard deviation under Article 4.2.3.1 shall be on strength tests performed after the previous year’s approved mix design date. No test shall be more than two years older than the previous year’s approved mix design date. Documentation showing the standard deviation and all other relevant calculations shall be provided.

Strength test results prior to 28 days are acceptable if they meet all other requirements.

Aggregates and Cementitious Material Submittals shall include (Online Form and Attached PDF Format):

- Contact information

- Source of material

- Aggregate and cementitious material submittals shall include all pertinent information regarding the specification and will be submitted to the MOC administrator. All submittals shall include a statement, from the testing agency, stating the material meets the requirements of the MOC specification and any current, prevailing referenced specifications.

- Test results, performed by a qualified laboratory, that meet the current MOC Specification for aggregates.

- Test results, performed by a qualified laboratory, that meet the current MOC Specification for Cement.

- Test results, performed by a qualified laboratory, that meet the current MOC Specification for Secondary Cementitious Materials.

The ready mix supplier shall provide testing results for ASTM C 1567 Mortar Bar Expansion. Expansion shall be a maximum of 0.10% at 16 days.

Mix designs shall be approved for the MOC year: January 1, 2019 through December 31, 2019.

Please send all submittal information through the website. Contact the CASPAR's Engineer with questions.

Engr. Muhammad Arif

CASPAR Associates (SME) Pvt. Ltd.

info@casparassociates.com

Tel. 0334.454.3333

CASPAR Associates (SME) Pvt. Ltd.

info@casparassociates.com

Tel. 0334.454.3333

Comments

Post a Comment