Prime Coat (MC-1)

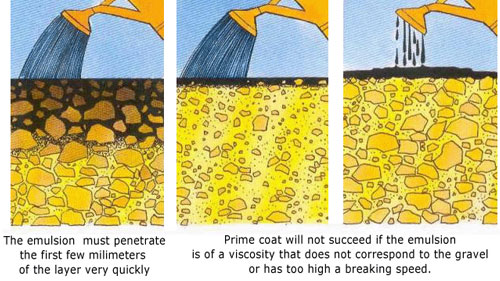

Prime coat typically is application of low viscosity Bitumen over a granular base, preparing it for laying an asphalt mixture on it. A prime coat performs several important functions. Coats and bonds loose material particles on the surface of the base. Hardens or toughens the surface of the base. Waterproofs the surface of the base by plugging capillary or interconnected voids Provides adhesion or bond between the base and the asphalt mixture. Bitumen emulsions used for Prime Coat are Cationic Slow Setting Emulsion 1 and Cationic Slow Setting Emulsion 2 as per latest MoRTH specifications.