Things to Consider about Hot Weather Concreting

THINGS TO CONSIDER ABOUT HOT WEATHER CONCRETE

When the temperature of freshly mixed concrete approaches approximately 32°C adverse site conditions can impact the quality of concrete. Ambient temperatures above 40°C and the lack of a protected environment for concrete placement and finishing (like enclosed building) can contribute to difficulty in producing quality concrete.

The precautions required to ensure a quality end product will vary depending on the actual conditions during concrete placement and the specific application for which the concrete will be used. In general, if the temperature at the time of concrete placement will exceed 32°C a plan should be developed to negate the effects of high temperatures.

The precautions may include some or all of the following:

- Moisten sub-grade, steel reinforcement, and form work prior to concrete placement.

- Erect temporary wind breaks to limit wind velocities and sunshades to reduce concrete surface temperatures.

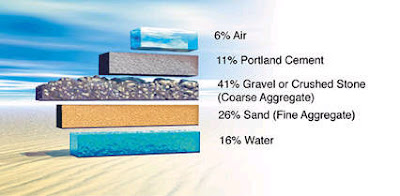

- Cool aggregates and mixing water added to the concrete mixture to reduce its initial temperature.

- Use a concrete consistency that allows rapid placement and consolidation.

- Protect the concrete surface during placement with plastic sheeting or evaporation retarders to maintain the initial moisture in the concrete mixture.

- Provide sufficient labor to minimize the time required to place and finish the concrete, as hot weather conditions substantially shorted the times to initial and final set.

- Consider fogging the area above the concrete placement to raise the relative humidity and satisfy moisture demand of the ambient air.

- Provide appropriate curing methods as soon as possible after the concrete finishing processes have been completed.

- In extreme conditions consider adjusting the time of concrete placement to take advantage of cooler temperatures, such as early morning or night time placement.

SETTING TIME

There is no limit for temperature of fresh concrete as delivered in hot weather in ASTM C94. ACI 301 and ACI 305, states a maximum temperature of (35°C) 95°F that can be modified by the project specification. Higher temperature limits are permitted based on mixture evaluation or local area practice.

With proper planning and execution concrete can be successfully placed and finished to produce high quality durable concrete at Ambient Temperatures of 40°C or less.

The effect of high ambient temperatures and high temperature concrete component materials have on the setting time of concrete mixtures is a topic of concern due to the reduced time in which concrete must be placed, consolidated and finished; increased potential for plastic shrinkage cracking, thermal cracking and cold joints; potential strength reduction due to high water demand and high curing temperatures; difficulty in controlling air content; and increased urgency for applying appropriate curing method at an early age.

As a general rule of thumb an increase of 12° will reduce the setting time of a concrete mixture by as much as 50%. As an example, a concrete mixture that reaches final set in three hours at 15°C may reach final set in as little 1½ hours at 27°C. As the concrete temperature increases the setting time is further reduced. The actual temperature of the concrete mixture as delivered is effected by the temperature of the materials used in the mixture, the cementitious content of the mixture, the temperature of the equipment used to batch and transport the concrete, and the ambient temperature and conditions at the project site. Concrete applications may be considered hot weather concrete at temperatures ranging from 27°C to 32°C depending on the specific application. Precautions should be planned in advance to counter the effects of high temperature well in advance of execution to counter these effects.

As a general rule of thumb an increase of 12° will reduce the setting time of a concrete mixture by as much as 50%. As an example, a concrete mixture that reaches final set in three hours at 15°C may reach final set in as little 1½ hours at 27°C. As the concrete temperature increases the setting time is further reduced. The actual temperature of the concrete mixture as delivered is effected by the temperature of the materials used in the mixture, the cementitious content of the mixture, the temperature of the equipment used to batch and transport the concrete, and the ambient temperature and conditions at the project site. Concrete applications may be considered hot weather concrete at temperatures ranging from 27°C to 32°C depending on the specific application. Precautions should be planned in advance to counter the effects of high temperature well in advance of execution to counter these effects.

Precautions may include use of materials with a good performance history in high temperature conditions, cool concrete materials or concrete mixture, provide concrete consistency and placement equipment and crew for rapid placement, reduce time of transport, schedule placement to limit exposure to atmospheric conditions (night time placement or more favorable weather), plan to limit rapid moisture loss (sun screens, wind screens, misting, or fogging), and consider the use of an evaporation retarder. Schedule a pre-construction meeting including all of the participants to discuss the plan to control the effects specific to the project and expected conditions.

Some concrete specifications contain a maximum temperature for the freshly mixed concrete as delivered. Typical ideal values are between 26.7°C and 35°C, while pouring on site as measured by ASTM C-1064-86. This can be modified in accordance with the project specifications.

ACI 305R Section 3.2.1 states that “concrete can be produced in hot weather without maximum limits on placing temperature and will perform satisfactorily if proper precautions are observed in proportioning, production, delivery, placing, and curing. As part of these precautions, an effort should be made to keep the concrete temperature as low as practical.”

As per experience, simple truth of the matter is that concrete placed and cured at a moderate temperature (15°C to 27°C) will outperform than +35°C concrete in strength and durability. If you are looking for superior concrete, control the temperature.

Comments

Post a Comment