Checklist for Good Concrete Mix Design

Achieving a proper concrete mix at the site is very difficult for a common man. Even for a Civil Engineer, it is very difficult to attain a good mix and a proper mix is very crucial for the durability and strength of the structure. Here are some very important points to check before going for a mix. These tips are aimed at laymen so I’m trying to use simple terms instead of technical terms.

Materials selection

Materials are to be properly tested in a lab and get approved by an engineer. If possible do a mix design by a Licence Holder Design Mix Engineer and do a strength test at 7, 28 days.

Test for aggregates

Water

Water used should be potable water i.e water used for drinking purposes that are free of chemicals and harmful minerals.

Apparatus required

The following apparatus should be provided at the site by the contractor at the time of concreting.

Check for clay and silt in the sand with a test tube, pour dry sand till 25 ml mark in a test tube adds water till 35 ml mark. Add a pinch of salt and shake vigorously. The clay will settle above the sand and calculate the percentage of impurities. Anything above 8% is not good.

Make sure all ingredients are uniformly dry mixed before adding water and this is the correct practice usually not followed as it is time-consuming.

Cement used must not be less than 3 months old. The month of manufacture will be indicated on the bag.

If the ISI mark is red in color it is PPC and the black color indicates OPC. PPC is preferred for residential structures and small commercial buildings.

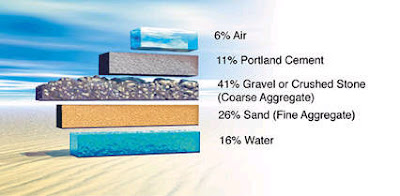

The nominal mix is M20 and for RCC other than footing C20 is mostly used. C20 means 1:1.5:3 ratio.

Quantity of mix must be taken in weight (Kg) only as per PS standards. But for small residential and commercial structures this cannot be ensured, for such cases as a “rule of thumb” proportioning by volume is also done.

If the aggregates used are wet, then water added must be reduced to compensate because wet aggregates carry a considerable amount of water.

Start with less water and gradually add more water, too much water will decrease the strength and less water will result in unworkable concrete.

The optimum water-cement ratio is 0.45- 0.7% and anything above this will affect the strength of concrete.

After mixing check for consistency and workability by slump cone test because slump cone test will give you an idea about the water-cement ratio.

Insist on concrete mixing by machine only, electric-powered, or fuel operated because this will ensure a more consistent mix.

Placing and compaction of concrete

After mixing place the concrete as soon as possible because placing concrete after 45 minutes of mixing will decrease the strength unless admixtures are used.

Compaction of concrete is usually done by needle vibrators and there must be at least 2 vibrators on site.

Minimum 3 spare needles must be present at the site because once the concrete is placed it must be compacted immediately. The initial setting of the concrete takes place at 30-45 minutes so the first 45 minutes after placing is very important.

Beam column joints are hard to reach place for vibrators so manual compaction must be done there.

Materials selection

Materials are to be properly tested in a lab and get approved by an engineer. If possible do a mix design by a Licence Holder Design Mix Engineer and do a strength test at 7, 28 days.

- Test for cement

- Finesse test

- Consistency test

- Soundness test

- Setting time

Test for aggregates

- Abrasion test

- Crushing value

- Impact test for 10-12 mm aggregates

- Shape test

- Specific gravity and water absorption

Water

Water used should be potable water i.e water used for drinking purposes that are free of chemicals and harmful minerals.

Apparatus required

The following apparatus should be provided at the site by the contractor at the time of concreting.

- Slump cone apparatus

- Cube molds to take concrete samples for testing (minimum 6 required)

- Beam molds if required, based on the scope of work.

- Test tube with graduated markings

Check for clay and silt in the sand with a test tube, pour dry sand till 25 ml mark in a test tube adds water till 35 ml mark. Add a pinch of salt and shake vigorously. The clay will settle above the sand and calculate the percentage of impurities. Anything above 8% is not good.

Make sure all ingredients are uniformly dry mixed before adding water and this is the correct practice usually not followed as it is time-consuming.

Cement used must not be less than 3 months old. The month of manufacture will be indicated on the bag.

If the ISI mark is red in color it is PPC and the black color indicates OPC. PPC is preferred for residential structures and small commercial buildings.

The nominal mix is M20 and for RCC other than footing C20 is mostly used. C20 means 1:1.5:3 ratio.

Quantity of mix must be taken in weight (Kg) only as per PS standards. But for small residential and commercial structures this cannot be ensured, for such cases as a “rule of thumb” proportioning by volume is also done.

If the aggregates used are wet, then water added must be reduced to compensate because wet aggregates carry a considerable amount of water.

Start with less water and gradually add more water, too much water will decrease the strength and less water will result in unworkable concrete.

The optimum water-cement ratio is 0.45- 0.7% and anything above this will affect the strength of concrete.

After mixing check for consistency and workability by slump cone test because slump cone test will give you an idea about the water-cement ratio.

Insist on concrete mixing by machine only, electric-powered, or fuel operated because this will ensure a more consistent mix.

Placing and compaction of concrete

After mixing place the concrete as soon as possible because placing concrete after 45 minutes of mixing will decrease the strength unless admixtures are used.

Compaction of concrete is usually done by needle vibrators and there must be at least 2 vibrators on site.

Minimum 3 spare needles must be present at the site because once the concrete is placed it must be compacted immediately. The initial setting of the concrete takes place at 30-45 minutes so the first 45 minutes after placing is very important.

Beam column joints are hard to reach place for vibrators so manual compaction must be done there.

Comments

Post a Comment