Concrete Testing

Design Mix:

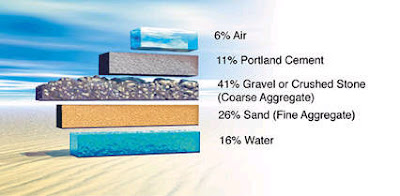

This test helps in determining the suitable ingredients of concrete and determining their relative amounts with the objective of producing concrete of the required strength, durability, and workability as economical as possible is termed as concrete mix design. It involves studying properties of Aggregate, Cement, Water & Admixture (if any), and is used to determine the proper Concrete Mix Design.

Ref: ACI 211.1

Ultrasonic Survey:

Ultrasonic concrete testing is based on the pulse velocity method to provide information on the uniformity of concrete, cavities, cracks, and defects. The pulse velocity in a material is directly proportional to its density and its elastic properties which in turn depends on the compressive strength and the quality of the concrete. It is, therefore, feasible to obtain information about the properties of components by sonic investigations.

Test Method: IS 13311 (Part 1)

Chloride Content:

Measuring the calcium chloride content of concrete is used to determine the dryness of concrete. This test is useful to tell if the concrete is ready for projects such as installing flooring on top of the concrete slab. Though some conditions can alter the results, such as the seasons of the year, the porosity of the concrete, or the mixture of the concrete, a calcium chloride test serves as a good indicator of the usability of concrete.

Test Method: IS: 6925-1973

Chloride Permeability:

The chloride permeability of concrete subjected to static and repeated compressive loading is evaluated by using this test method. The test results indicate that the chloride permeability of concrete subjected to static and repeated loading at a gradually increasing rate and its residual strain. This test covers the determination of the electrical conductance of concrete to provide a rapid indication of its resistance to the penetration of chloride ions.

Test Method: AASHTO T277

Chloride Ponding Test:

This test helps in determining the depth to which chloride ions can ingress into the concrete over a period of time under standard conditions. It is used to assess concrete for its resistance to chloride attack and thus protection of the reinforcement from corrosion.

Test Method:

Cube Compressive Strength:

The cube test is most commonly used for determining the value of compressive strength that can be used to assess whether the batch that the concrete cube represents, meets the required compressive strength or not. A cube of concrete in the cast is cured for the appropriate time and is then compressed between two parallel faces.

Test Method: IS: 456, IS: 15658-2006, IS: 516-1959

Depth of Carbonation:

Carbon dioxide penetrates the concrete pores. This penetration is faster when concrete is more porous. It can then react with cement to form carbonates. This reaction decreases the concrete pH so, carbonation starts on the concrete surface and concerns some thickness (called carbonation depth) of the material. Carbonation is a typical form of deterioration. Enough carbonation gives concrete the immediate positive effects of increased, compressive strength, modulus of elasticity, surface hardness, resistance to frost, sulphate attack, internal stresses, and the ultimate reduction of the structure’s capacity.

Test Method:

Drying Shrinkage/ Wetting Expansion Test:

A common saying is that there are two guarantees with concrete. One, it will get hard and two, it will not crack. Cracking is one of the major causes of complaints in this industry. Cracking can be the result of one or a combination of factors such as drying shrinkage, thermal contraction, restraint (external or internal) to shortening, subgrade settlement, and applied loads. Values of wetting expansion and drying shrinkage of concrete are often useful during the time of mix design trials to ensure that concrete will exhibit values that are within normal ranges.

Test Method: IS: 1199-1959

Flexural Strength Test:

Flexural Strength is the ability of a beam or slab to resist failure in bending. It is measured by loading un-reinforced 6×6 inch concrete beams with a span three times the depth (usually 18 in.).

Test Method: IS: 516-1959, ASTMC 494-2010

Porosity:

Concrete durability is related to porosity, which determines the intensity of interactions of the material with aggressive agents. The pores and capillaries inside the structure facilitate the destructive processes, that generally begin at the surface. Generally, concrete of a low porosity can afford better protection than concrete of high porosity. Porosity can be measured by vacuum saturation of a concrete specimen, measuring its weight gain and expressing this as a percentage of the mass of the sample.

Test Method:

Sulphate Content:

Measuring the Sulphate content of concrete is used to check that the sulphate levels are low enough to avoid any later problems with deterioration of the concrete. This test can be used at concrete mix design stage to ensure low sulphate levels have been achieved, or on older concrete structures to measure the level of ingress of sulphate. Tests can be conducted through multiple types of chemical means.

Test Method: BS: 812(P-118)

Water Absorption Test:

This test helps in determining the rate of absorption of water in cement concrete by measuring the increase in the mass of a specimen resulting from absorption of water during the time when one surface of the specimen is exposed to water. The exposed surface of the specimen is immersed in water and water ingress of unsaturated concrete dominated by capillary suction during initial contact with water.

Test Method: ASTM C 1084

Water Penetration Test:

Water penetration is used to measure the surface hardness and the strength of layers near-surface of the concrete. Water penetration causes the concrete reinforcement to rust and expands which in turn creates stress on the surrounding concrete.

Test Method: ASTM C 1084

Pile Integrity Test (PIT):

This test is done to measure Pile length, depth to anomalies, Pile head stiffness, Pile shaft mobility – which is dependent on pile section and concrete properties.

Test Method:

Admixture:

Concrete Admixture is a chloride-free, high-range, water-reducing admixture. It disperses the fine particles in the concrete, enabling water content in the concrete to perform more efficiently and improve the consistency of concrete.

Test Method: IS: 9103 / 1999

Rebound Hammer Test

Rebound Hammer Test is done to find out the compressive strength of concrete by using Rebound Hammer as per IS: 13311 (Part 2): 1992. The rebound of an elastic mass depends on the hardness of the surface against which its mass strikes. When the plunger of the rebound hammer is pressed against the surface of the concrete, the spring-controlled mass rebounds, and the extent of such a rebound depends upon the surface hardness of the concrete. The surface hardness and therefore, the rebound is taken to be related to the compressive strength of the concrete. The rebound value is read from a graduated scale and is designated as the rebound number or rebound index. The compressive strength can be read directly from the graph provided on the body of the hammer.

Core Cutting Test on Concrete

This is a partially destructive test that is used to co-relate various properties of the concrete viz. UPV, electrical resistivity, rebound number, etc. It is customary to take cores of 4-inch diameter for compressive strength determination. Concrete core drilling for strength determination is again dependent upon various factors for reliability. The conversion of concrete core (typically 3 or 4-inch diameter core) strength into 150 mm saturated cube strength depends upon:

- effect of coring

- shape factor

- size effect

- the direction of coring w.r.t. the placing of concrete

- h/d ratio

With so many factors contributing to the final 150 mm saturated cube strength, the strength variation may be + / – 10% – 15%. However, it can be used to confirm the results of UPV differ largely in the values & also for co-relation. Hence the UPV & core results should be judiciously used, interpreted & co-related.

Comments

Post a Comment