Concrete Mix Design (M20 Grade)

- Volume Batching

- Weigh Batching

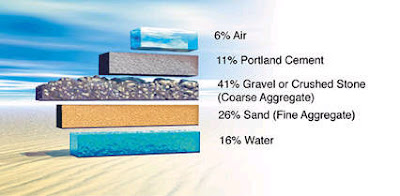

M20 (1 cement :1.5 sand :3 stone/brick aggregate). To determine the proportions you have to perform mix design, you have to find out the Specific Gravity of cement, CA, FA, and water-cement ratio, type of exposure, Maximum size of aggregate, etc. Once the W/C ratio is determined use 186 kg water (for 20mm CA) to find out the qty. of cement per cum of concrete. Then determine the qty. of FA and CA with the help of the formula given in IS:10262-1982, and then divide all the ingredients by cement, then you will get the proportion similar to you mentioned which are in kg. Or you can follow IS:10262 -2009, where the calculations are easier.

1. REQUIREMENTS

a) Specified minimum strength = 20 N/mm2

b) Durability requirements

I) Exposure Moderate

ii) Minimum Cement Content = 300 Kgs/m3

c) Cement (Refer Table No. 5 of IS:456-2000)

I) Make Chetak (Birla)

ii) Type OPC

iii) Grade 43

d) Workability

i) Compacting Factor = 0.7

e) Degree of Quality Control: Good

2. TEST DATA FOR MATERIALS SUPPLIED

a) CEMENT

i) Specific gravity = 3.05

ii) Avg. comp. strength 7 days = 46.5 more than 33.0 OK

28 days = 55.0 more than 43.0 OK

b) COARSE AGGREGATE

i) 20mm Graded

Type Crushed stone aggregate

Specific gravity = 2.68

Water absorption = 1.46

Free (surface) moisture = 0

c) FINE AGGREGATE (Coarse sand)

i) Type Natural (Ghaggar)

Specific gravity = 2.6

Water absorption = 0.5

Free (surface) moisture = 1.4

3. TARGET MEAN STRENGTH (TMS)

a) Statistical constant K = 1.65

b) Standard deviation S = 4.6

Thus, TMS = 27.59 N/Sqmm

a) As required for TMS = 0.5

b) As required for ‘Moderate’ Exposure = 0.55

Assume W/c ratio of 0.5

5. DETERMINATION OF WATER & SAND CONTENT

For W/C = 0.6

C.F. = 0.8

Max. Agg. Size of 20 mm

a) Water content = 186 Kg/cum

b) Sand as a percentage of total aggregate by absolute volume = 35 %

Thus,

Net water content = 180.42 Kg/cum

Net sand percentage = 33 %

6. DETERMINATION OF CEMENT CONTENT

W/c ratio = 0.5

Water content = 180.42 Kg/cum

Thus, Cement content = 360.84 Kg/cum Adequate for moderate exposure Say 360 Kg/cum

7. DETERMINATION OF COARSE AND FINE AGGREGATE CONTENT

Assume entrapped air as 2 %

Thus,

0.98 cum = [180.42+360/3.05 + {1/0.33}*{fa/2.6}]/1000

& 0.98 cum = [180.42+360/3.05 + {1/0.67}*{Ca/2.68}]/1000

Hence,

fa = 584 Kg/cum

Ca = 1223.8 Kg/cum

The final mix proportions of M-20 grade of concrete become:-

Comments

Post a Comment