Method Statement for Asphalt Paving Works

Method Statement for Asphalt Paving Works

(Civil

Engineering)

Effective Date:

Document No.:

Approved By: Eng. Muhammad Arif

PROJECT NAME: --------------------------------------------------------------------------

2). INTRODUCTION

HEALTH, SAFETY & ENVIRONMENT

(HSE)

HEALTH, SAFETY & ENVIRONMENT

(HSE)

Emergency Procedure

Emergency Procedure

Document No.:

Approved By: Eng. Muhammad Arif

PROJECT NAME: --------------------------------------------------------------------------

SAMPLE 1

TABLE OF CONTENT

1.

ACTIVITY

2.

INTRODUCTION

3.

TERMINOLOGY

4.

SIGNIFICANT HAZARDS IDENTIFIED

5.

ROLES & RESPONSIBILITY AND

ORGANIZATION CHART

6.

SEQUENCE OF ACTIVITIES WITH

RESPONSIBILITIES

6.1 Pre-commencement Requirements

6.2 General Requirements

6.3 Co-ordination with Other Trades

6.4 Delivery, Storage & Handling of

Materials

6.5 Execution

7.

REQUIREMENTS

7.1 Plans/Records & Job instructions (Documentations)

7.2 Training

7.3 PPE (Personal Protective Equipment)

7.4 Equipment & Tools required

8. HSE & Emergency Procedures

9. ReferenceS

10. AttachmentS

- ACTIVITY: LAYING OF ASPHALT ROAD

This activity deals with the installation

and sequence of Laying of Asphalt road as per approved drawings and project

specifications and to ensure that the works are carried out in accordance with

the HSEQ documents.

2). INTRODUCTION

The

purpose of this method statement is to describe the procedure which shall be

followed for Laying of Asphalt road to comply with

schedule of finishes, the General, Architectural & Civil Specifications for

the Project and Owner / Engineer requirements.

3). TERMINOLOGY

O/E: Owner /

Engineer

PPE: Personal Protective Equipment

QC: Quality Control

4).

SIGNIFICANT HAZARDS IDENTIFIED

·

Respiratory hazard

·

Injury to person

·

Wrist Pain/Stress/fatigue

·

Slip/trip/fall hazards

·

Back injury

·

Vehicles movement

·

Sharp edges

·

Cut Injury

·

Injury to Eye/Eye Irritation

·

Chemical usage hazard

·

Machinery

·

Work related upper limb disorders

·

Electric Shock

5).

ROLES & RESPONSIBILITIES AND ORGANIZATION CHART

· Project Manager

(Main Contractor)

o

The project

manager is responsible for overall implementation of this Method Statement and

HSEQ related to this activity.

o

Ensure that the Site

construction and his team will aware of this Method Statement

o

Site construction

and his team will report to the project manager.

· Construction Manager

(Main Contractor)

o

Make arrangement

for availability of all relevant documents.

o

Ensure the availability of

necessary documents & resources available with Subcontractor.

o

Liaison with Owner/Engineer &

Subcontractor in-charges for necessary test & inspection.

o

Tracks the schedule & plan work

accordingly.

o

Liaison with all Electrical/MEP

work in-charges for all interfaces works and plans the work accordingly at

site.

· Engineer (Main

Contractor)

o

Ensures the control at work spots

in person.

o

Verifying the percentage compliance

as per risk assessment.

o

Ensures the emergency preparedness

of team and taking the part in Subcontractor’s TBT (Tool Box Talk)

o

Ensures the work carried out as per

latest approved drawings.

o

Ensure availability of necessary

resources and approved documents.

o

Inspects the incoming materials in

line with approved documents.

o

Ensure the quality

of work/material and readiness for inspection.

· Safety Officer

(Main Contractor)

o

Responsible for ensuring HSE at all

stages of work.

o

Ensures the compliance of all control

measures at site as per approved risk assessment plan.

o

Ensures for all

checklist as per HSE plan.

· Project Manager

(Subcontractor)

o

Ensure that

appropriate resources are provided for the safe delivery of the work

· QA/QC Engineer

(Subcontractor)

o

Ensuring quality of work carried

out at site

o

Ensuring for inspection on hold

points

o

Maintaining all QC records

o

Coordinating with

O/E for inspections

· Site In charge

(Subcontractor)

o

Ensuring the relevant document

o

Plans the

necessary men and material resources for

timely completion and quality

· Site Engineer

(Subcontractor)

o

Ensuring the controls at work spot

in person

o

Verifying the % compliance as per

risk assessment.

o

Ensuring the emergency

preparedness.

o

Arranging the required inspections

and permit

o

Ensures all scaffolding

erected safely and scaffolding tag

system followed

o

Ensures availability of the

necessary resources.

o

Ensuring

availability of all activity relevant latest approved drawing and documents

· Supervisor /

Foreman (Subcontractor/Supplier)

o

Obtaining the permit (if required

-e.g. Steel cutting)

o

Conducting Tool Box Talk (TBT) based on risk assessment

o

Arranging for appropriate tools and

necessary skilled work force as required.

o

Ensuring the works are carried out

as per approved and latest drawing/documents

o

Ensuring for Housekeeping always at work place

o

Implementing the control measures

as per risk assessment and also as mentioned in the permit.

o

Close monitoring till completion of

work.

o

Close the work

permit after restoration of work spot.

· Workmen (Subcontractor/Supplier)

o

Wearing appropriate PPEs.

o

Understanding and following the

instructions given by line staff.

o

Following the scaffolding tag

system

o

No horseplay and shortcuts.

o

Informing the

supervisor/foreman about any near misses, injuries and unusual

· Safety

Officer (Subcontractor)

o

Ensures all safety measures

implemented/followed as per risk assessment and HSE Plan

o Should inform the site engineer for

any deviations from required procedure/standard practice

o

Should conduct a safety briefing in

co-ordination with site engineer/supervisor over a specific HSE issue

o

Ensure all First aid cases are

entered in first aid register and

necessary awareness given to the victim

o

Ensures for

inspection of power tools and scaffolding

· Surveyor

(Subcontractor)

o

To check the levels, coordinates

and alignments of every work activity at site.

· Organization Chart

(see for attachment)

6). SEQUENCE OF ACTIVITIES WITH RESPONSIBILITIES

6.1

Pre-commencement

Requirements

· Approval of work procedures shall be

obtained from O/E prior to the start of activity.

· Asphalt mix design test results

shall be submitted to the O/E’s review.

· Safety regulations as per

specifications and standard shall be followed

6.2

General Requirements

Before start of the work the following

shall be ensured:

· Tools, Equipment & Machinery is

suitable and approved for use.

· Availability of suitable quantity of

approved material for the works as per specification and O/E requirements.

· Area clearance obtained from other

discipline/subcontractor.

6.3

Co-ordination

with other trades

· No Laying of asphalt road work to be

started unless it is cleared for Laying works.

· Prior to start the works, check all

architectural, mechanical and electrical works are completed and MEP clearances

shall be taken as required.

6.4

Delivery,

Storage & Handling of Materials

· All materials shall comply with the

specifications regarding quality, dimensions, strength etc.

· The material shall be approved and

shall be used as per the Approved drawings.

· Materials received at site shall be

checked by O/E.

· Sampling / testing to be done as per

requirements of specification

6.5

Execution

: Procedure for laying Asphalt road works

A) Surface Preparation

· The

surveyor shall mark the road center line and width of the embankment prior to

starting of any road works; The CONTRACTOR shall make detail survey of the

existing services (If any) by the side of the road or crossing the road

· Surveyor shall make a survey report for the

existing levels prior to filling or cutting and engineer should make sure for

the same

· All the

road works and road crossings must be executed as per the approved drawings and

as per project specifications.

B) Road embankment

·

Embankment

shall be installed on top of the existing natural ground, thickness of this

layer shall be at least 30 cm

·

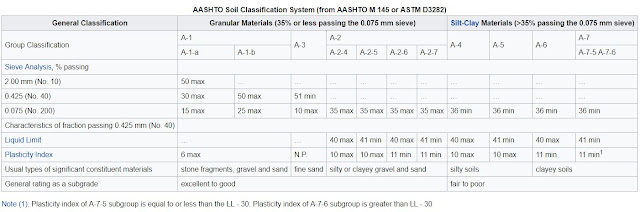

Material

to be used for road embankment shall be A-1-a OR A1-b or A-2-4 in accordance

with AASHTO Soil Classification System (from AASHTO M 145 or ASTM D3282).

· Every

layer should be compacted with heavy compactor and the compacted density of the

soil shall be equal to or greater than 95% M.D.D., with no single value below

92%.

C) Sub-Grade

· Ensure that approved sub-grade material is

used and the material sample shall be collected and tested as per project

specifications upon receiving of material at site.

· Sub-grade material shall be placed above

embankment filling

· The approved Sub-grade material shall be back-filled to the thickness of 300 mm and it should back-filled in two layers

(each layer 150 mm ).

· Compaction of sub-grade shall be

facilitated by means of a 10-12 ton roller, rolling shall be continue to

achieve the Max. Dry Density(MDD) of 98% as per approve drawings and project specifications.

· Thickness of sub-grade shall not be less

300 mm as specified in the approved drawings

· The formation shall be shaped and graded

to an even and uniform, well filled surface, shaped similarly to the finished

surface of the road

· Compaction test shall be done by approved

laboratory for the Sub grade.

D)

Laying of Kerbstones

·

The above

work shall be carried out according to the Method statement submitted vide WS-CRN-DAR-CV-MS-1360 dated 22.10.2018.

·

Laying of Kerb stone shall be inspected and approved by O/E.

E)

Sub-Base

· Ensure that approved sub-base course

material is used and the material sample shall be collected and tested as per

project specifications upon receiving of material at site.

· Thickness of sub-base course shall be 200 mm

as specified in the approved drawings, and it shall be placed in two layers.

· Sub Base material spreading shall be

started after receiving the compaction test results of Sub Grade.

· Sub-base material loads shall be spread outside

area on which it is spread to ensure that no segregation occurs and it shall be

spread evenly using a grader to maintain the levels and thickness of layers.

· Each layer shall be must be compacted to an average of 100% of

MDD with no single value below 98%

· Minimum field density tests shall be one

test for every 300 m2 of

granular sub-base laid

· Minimum material test requirement shall be

one sample for every 1,000 cum of material and test shall be as follows grading,

plasticity index, sand equivalent, MDD, and CBR, loss by abrasion by the

approved laboratory as per the project specifications.

F)

Aggregate Base Course (ABC):

· Ensure that approved sub-base course

material is used and the material sample shall be collected and tested as per

project specifications upon receiving of material at site.

· Thickness of sub-base course shall be 150 mm

as specified in the approved drawings.

· Aggregate base course material spreading

shall be started after receiving the compaction test results of Sub Grade.

· Aggregate base course material loads shall

be spread outside area on which it is spread to ensure that no segregation

occurs and it shall be spread evenly using a grader to maintain the levels and

thickness of layers.

G)

Prime Coat (MC1):

· Ensure that approved material is used and

each consignment test certificate for prime coat (MC-70) shall be provided.

· Prime coat shall be tested as per project

specifications.

· Prime coat shall be applied between road

base course and bituminous base course as per approved drawings

· The same shall be cured for a curing

period of 48 hours prior to laying of bituminous base course

· Bituminous material for the prime coat

shall be applied in quantities of at least 0.7 ltr/m2, not exceeding

however 1.50 ltr/m2.

H)

Bituminous Base Course (BBC):

· Ensure that approved Bituminous base

course material is used and each consignment test certificates shall be

provided for Asphalt cement used (AC 40-50).

· Bituminous base course shall be of

thickness 90mm as per approved drawings.

· Bituminous base course shall not be placed

during dusty, foggy and Rainy weather.

· Bituminous base course material shall be

transported in trucks from hot mix plant & its final placement temperature

shall not be less than 150º C.

· Consistency of mixture shall be checked

for each 200 tons.

· Site engineer in coordination with

surveyor must ensure laying of bituminous course to the correct levels and to

the specified longitudinal and cross section profiles.

· The Bituminous base course shall be evenly

placed by mechanical spreader on a clean base in a manner that it does not

become segregated.

· The seams of the bituminous base course

shall be sufficiently staggered against each other and it should be executed

straights, longitudinal if necessary being adapted to the road alignment.

· Bituminous base course shall be compacted

evenly over the entire surface by using pneumatic & steel roller.

· Gradient slope shall be maintained as per

approved drawings.

· The core sample to be taken after

compaction to determine the layer thickness and the MDD as per project

specifications.

I)

Tack Coat (RC2):

· Ensure that approved material is used and

each consignment test results shall be provided for Tack Coat (RC2).

· Tack coat shall be tested as per project

specifications.

· Tack coat shall be applied between

bituminous base course and the wearing course as per the Project Drawings.

· Tack coat shall be cured for at least 1

hour

·

Tack coat

shall be applied in quantities of at least 0.3 ltr/m², not exceeding,

however 0.60 ltr/m²

J)

Wearing Course (BWC):

· Ensure that approved material is used and

each consignment test certificates shall be provided for Asphalt Cement used

(AC 40~50).

· Temperature of mixture to be measured at

site and it should not less than 1500C.

· Consistency of mixture shall be checked

for each 200 tons.

· Thickness of wearing course shall be 60 mm

as per approved drawings

· Wearing course shall be placed in one

layer above the bituminous base course and one coat of tack coat shall be

applied between bituminous base course and wearing course.

· The Wearing course shall be evenly placed

by mechanical spreader on a clean base in a manner that it does not become

segregated.

· The seams of the wearing course shall be

sufficiently staggered against each other and it should be executed straights,

longitudinal if necessary being adapted to the road alignment.

· Wearing course shall be compacted evenly

over the entire surface by using pneumatic & steel roller.

· Site engineer in coordination with the

surveyor must ensure the top levels and slope is maintained as per approved

drawings.

· The core sample to be taken after

compaction to determine the layer thickness and the MDD as per project

specifications.

K) Temperatures

· Temperature shall be checked whenever

material is delivered to site

· Aggregate ingredient shall be heated to a

temperature between 160ᵒ to 179ᵒC

· Asphalt cement shall be heated to a

temperature between 146ᵒ and 156ᵒ C at mixing time

· All bituminous mixtures shall leave the

paver at a temperature not less than 150ᵒC

· Prime coat (MC1) between 50ᵒ and 80ᵒC

· Tack Coat (RC2) between 10ᵒ and

50ᵒC

L) Joints

· Longitudinal joints in asphalt courses

shall be offset by 300 mm in relation to the longitudinal joints of the

underlying course

· Transverse joints in succeeding layers

shall be offset by at least 2 m. The same shall apply when new pavement is laid

in contact to an existing, which will be cut back in steps, 2m wide in each of

its layers

· At transverse joints the previously laid

work shall be cut to a vertical edge. Before laying the material against it,

the vertical edge to be painted with hot bitumen

· Minimum number of joints to b

exercised/considered during execution

M) Compaction of Mixtures

· After spreading and strike-off, the

rolling operation by pneumatic and stell roller shall start immediately and

shall operate as close as possible to the paver without excessive tearing

· Rolling will not be prolonged till cracks

appear

· The asphalt layer shall be compacted to a

minimum degree of 98% of compaction

N) Thickness of Cores

· Depth of each bituminous paving course

shall be measured by cored samples

· Samples shall be one sample for 600 M²

· Cored sample shall be 10 cm in diameter

(nominal)

O) Surface Tolerances

v Non Bituminous Courses

· The

thickness and cross section as shown on the approved drawings shall not vary

more than -5 mm to +10 mm from the required elevations.

v Bituminous

Courses

·

Maximum

variations allowed for 3 M shall be :

Ø Base Course = 4 mm

Ø Wearing Course = 3 mm

P) Road Markings

·

Road markings shall be

applied wherever necessary or as directed by ENGINEER to control and direct the

traffics.

·

Road markings shall be

marked by thermoplastic as per project specifications.

·

Road markings shall be

sprayed on the road in an even thickness of 2.0 mm.

Q) Inspection and Testing

·

Each activity like back-filling of Sub grade

and Sub base, In-situ Density test for Sub base & Sub grade and laying of Bituminous

base course and Wearing course work shall be intimated to O/E through

inspections.

·

After due completion of laying of Asphalt

work shall be offered to O/E’s inspection and comments on the work shall be

rectified and notified for re-inspection if any.

·

Testing of

each consignment delivered to the site shall be carried out as per the

specifications for road works of RIYADH AMANAH.

7). REQUIREMENTS

7.1

Plans /Records and Job instructions

(Documentations)

Before

commencing the work the following things should be available:

·

Inspection request for materials, erection

& installation

·

Approved drawings / Material

approval for the work

·

Method statement for the work

·

Key site plan for that work area

·

All inspected tools &

machineries

· Emergency

escape route without obstructions

· Clearance

from Electro-Mechanical incharge

7.2 Training

· Trained/Experienced

& Skilled persons shall be used for the work

· All

operator / Laborers are safety trained and toolbox shall be conducted for the

each potential hazards mentioned in the Risk assessments.

7.3

PPE (Personal Protective Equipment)

· Protective

clothing

· Protective

gloves

· Safety

helmet

· Safety

goggles

· Hard

Gloves

· Hi-visibility

jacket

· Flagging

tape

· Warning

tape

· Flasher

light

· Safety

Harness (above 1.8m)

7.4

Equipment and Tools required

·

Manpower requirement

1.

General Supervisor/Foreman - 01 no

2.

Charge hand - 02 nos.

3.

Mason - 02 nos

4.

Helpers - 06 nos.

5.

Electrician - 01 no.

·

Equipment

1.

Shovel

2.

Compaction roller machine

3.

Spreader

4.

Trucks

5.

Sprit level

6.

Plumb bob

7.

Electric air blower/Air compressor

for cleaning

8.

Drilling Machine

9.

Hammer

10.

Measuring Tapes

11.

Marker

7.5 Risk Assessment

·

Risk assessment to be ensured that

it is available in the work spot

·

All control measures as per risk

assessed to be implemented and ensured before start of work

·

All workers shall be made aware of

the risk involved in carrying out the activity and requirement of control

measures during toolbox talk

8). HSE

& EMERGENCY PROCEDURES

v The entire works will be

carried out as per the guidelines established in the Project Specific HSE Plan

v Utmost importance shall

be given to safety or personnel and protection of existing above/under ground

services. It will be ensured that the personnel involved are thoroughly aware

of the safety regulations. To achieve the above the following shall also be

ensured:

·

Tool

box meetings will be conducted before starting the works

·

All

personnel will be provided with suitable personal protective equipment

·

Required

permits will be obtained from the authorities concerned before starting the

works, if any

·

Plant

& equipment will be fully tested for safety compliance

·

Proper

and safe access will be provided for workers to reach the work spot and carry

out their works safely

·

Necessary

and essential lighting and ventilation will be provided during the course work

to protect labor from suffocation

·

Scaffolding

and working platforms provided to facilitate the works will be checked

frequently for its safety

·

The

necessary safety measures will be taken to prevent accident or injury all the

times. This may include barriers, warning tape / net, signage, watchman,

flashing & rotating lights at night

·

Heat

Stress training will be provided during summer season

·

Provision

of adequate cool drinking water, shades if necessary will be arranged in place

·

Plants

& Equipment will be provided with back-up lights and all other applicable

safety devices

· In case of any emergency

situation the workmen should follow the emergency response procedure and must

gather in the assembly point. The emergency response procedure should be

conveyed to the work men through the toolbox talk in prior to the carrying out

of the activity.

· The necessary safety

measures will be taken to prevent the accident or injury all the times. This

may include barriers, warning tape, net, signage, watchman, flashing &

rotating lights at night.

· MSDS shall be made

available prior to the start of the job

· Heat stress training

will be provided during summer season.

· Provision of adequate

cool drinking water, shades if necessary and salt tablets will be in place.

· Plants & equipment

will be provided with back up lights and all other applicable safety devices.

v In case of major

Injuries

Ø Do

not panic. Call ambulance and notify emergency team at site

Ø Do

not move the injured unless he is in danger

Ø If

danger exists, he shall be assessed by a trained and qualified first aider

before moving. Use a stretcher.

Ø Do

not crowd around the victim. Do not give anything to eat or drink. Ensure adequate air and lighting.

Ø Only

trained and qualified first aider shall treat the victim and ensure that his

airway is kept clear.

Ø Victim

shall be transported to hospital in an ambulance.

Ø Preserve

the accident scene for further investigation.

v In case of Fire

Ø Follow

Amanah/s approved emergency procedure as per HSE Plan.

v In Case of Flood

Ø Evacuate

immediately to the nearest highest location you are in.

Ø Notify

the Emergency Controller of the site

v EMERGENCY CONTACT

NUMBERS:

Name

|

Position

|

Contact Nos.

|

Project Manager

|

||

Site Manager

|

||

Safety Officer

|

||

Fire Fighter / First Aider

|

||

Pick Up driver

|

POLICE

|

999

|

AMBULANCE

|

998

|

FIRE SERVICE

|

997

|

HOSPITAL

|

HMG

011 4909999

|

9). REFERENCES:

§ S-TR-CIVIL-Road (Rev.0-2010)

§ Project Quality Plan (PQP)

§ Project HSE Plan

§ Drwg. No. N7204.1E-R-E-5370-S-7151 Rev. A Sheet 1~1

§ Drwg. No. N7204.1E-R-E-5370-S-7201 Rev. A Sheet 1~1

§ Drwg. No. N7204.1E-R-E-5370-S-7212 Rev. A Sheet 1~2

§ Drwg. No. N7204.1E-R-E-5370-S-7401 Rev. A Sheet 1~1

§ Drwg. No. N7204.1E-R-E-5370-S-7402 Rev. A Sheet 1~1

§ Drwg. No. N7204.1E-R-E-5370-S-7351 Rev. A Sheet 1~1

§ Drwg. No. N7204.1E-R-E-5370-S-7352 Rev. A Sheet 1~1

§ Drwg. No. N7204.1E-R-E-5370-Q-7001 Rev. A Sheets 1~7

§ Drwg. No. N7204.1E-R-E-5690-H-7113 Rev. A Sheets

§ Ref. No. N7204.1E/MASS/0235- ASPHALT MIX DESIGN

10).

ATTACHMENTS:

ü S-TR-CIVIL-Road (Rev.0-2010)

ü Organization Chart

ü Risk assessment sheets

ü Approval

copy of Asphalt Mix Design

ü Standard

Drawings

ü Reference

Drawings

--------------------------------------------------------------------------------------------------------

Method Statement for Asphalt Paving Works

(Civil Engineering)

Effective Date:

Document No.:

Approved By: Eng. Muhammad Arif

PROJECT NAME: --------------------------------------------------------------------------

Document No.:

Approved By: Eng. Muhammad Arif

PROJECT NAME: --------------------------------------------------------------------------

SAMPLE 2

1. Scope:

The scope of work of

this method statement is to describe the responsibilities of personnel

involved, execution procedure, safety factors and documents to be recorded for

Asphalt Paving Works.

2. Relevant Process/Specifications:

Tender Specifications

3. Responsibility:

The Construction

Manager/Project Engineer is responsible for the asphalt paving works.

The Civil Construction

Contractor’s Safety Officer shall ensure that necessary work permits are

availed before the work commences and that the work is carrying out in safe

manner.

The responsibility of

the survey activities lies with asphalt paving work subcontractor. The survey

team of civil construction contractor shall verify the data frequently.

Inspection and testing

activities shall be controlled by the QC Engineer of Civil Construction

Contract or through the site laboratory of Company.

4. Plants and Equipment:

Bitumen spray tankers,

asphalt paver, Tandem steel roller, hand rollers, asphalt batching plant, etc.

5. Execution Procedure:

Prior

to Commencement:

Safety:

Prime importance shall

be given for personnel safety and protection of utility lines/services. It

shall be ensured that the personnel involved are aware about the Company Safety

regulation and confirm that the machinery are regularly maintained. Further

to above, the following key points shall be considered important.

a. Copies of

drivers/operator’s license vehicle’s registration and security passes to be

submitted to Company safety department before commencing the work.

b. All moving

vehicle/equipment shall have reverse horn.

c. Transporting of

persons per vehicle is restricted to the number of seat belts available in the

pickup.

d. Deep excavations

shall be adequately shored, barricaded and warning signs & lights shall be

posted.

e. Road safety

signs/road diversion signs shall be installed wherever applicable for the safe

movement of vehicles and equipment.

f. All major equipment

shall be tested and certified by Third Party prior to mobilization to site.

Existing

Services and Facilities:

a) Before commencement

of the work, ascertain the nature and location of all existing above and

underground services at site by visual survey and reviewing the service layout

drawing (if available)

If any protection, re

-routing, termination or removals of services are required for the smooth

progressing of work, it shall be discussed and written approval shall be

obtained from employer/ company as appropriate. For service protection,

approved method of protection shall be adopted.

b) A warning tape shall

be tied at a distance of 2 meters away from the services/as warning sign, to

restrict the movement of the equipment.

Survey:

a) Establish and protect

sufficient number of stations to re-establish the stations if they are

disturbed during work.

b) Post wooden stack for

line and gradient of the road.

c) The existing sand

tracks shall be blocked, re-routed and traffic diversion signs shall be posted

prior to the commencement of the work.

In-Process

Procedure:

The execution procedures

shall be divided into following sections, which are:

a) Prime Coat.

b) Binder course.

c) Tack coat.

d) Wearing course.

a)

Prime Coat (MC1):

Quality of Primer should

be as per BS:1707

Immediately before

applying the prime coat (which shall be preliminary approved), the full width

of the surface shall be cleaned with compressed air (Using Compressor).

i) The bituminous

material for the prime coat (MC1) shall be applied by means of bitumen spray tankers.

ii) This shall be

applied in a single layer at the rate of 0.7 – 1.5 liters /m² and at a

temperature not exceeding 70° C. This surface shall be cured for 24 hours.

iii) The over spread

area shall be cured more than 24 hours/ until excess prime coat is evaporated.

b) Bituminous Binder Course (BBC):

Quality of Binder should

be as per AASHO-T182

i) Immediately before

paving the binder course material (Bituminous Binder Coarse - BBC), the surface of the prime coat shall be

cleaned with compressed air and shall be ensured that the surface is dry.

ii) The hot asphalt mix

shall be brought from the approved mixing plant by 6 wheel trucks or trailers. Upon

arrival at site, the asphalt mix shall be dumped into the asphalt paver.

iii) The asphalt paver

shall lay the material to the required thickness and level.

iv) The mix shall be

compacted as soon as possible after spreading the material. Tandem rollers

shall follow the laying operation to carry out breakdown rolling up to

temperature of 110°C- 120° C. Pneumatic tired rollers and tandem rollers shall follow the breakdown

rolling and sufficient passes shall be made to achieve the required compaction.

Rolling shall start from

the sides and proceed toward the center. Each trip of the roller shall overlap

the previous trip by at least 30 cm. Roller wheel shall be kept moistened. The

roller shall be capable of reversing without backlash and shall be free from

worn parts.

Heavy rollers shall be

used to complete all rolling including elimination of waves caused by the

lighter rollers. Full compaction shall be obtained before the asphalt

temperature reaches 100°C. Compaction shall be in accordance with specification

of relevant standard.

v) The construction

joints shall be prepared by cutting the layer vertically down by means of

asphalt saw cutting machine or with jack hammer. The joint shall be cleaned

well by compressed air and tack coat (RC2) material shall be applied on the vertical

and horizontal surface for better bonding. Extremely good care shall be taken

when asphalt is laid at construction joints.

vi) The areas inaccessible

for heavy rollers shall be compacted with plate compactors or hand tampers.

After reaching the base course top level, suitable fill material (Dune Sand)

shall be dumped to the top level of base course on the sides of road shoulders.

It shall be leveled, shaped (1:6 Ratios) and compacted to 90% maximum dry

density.

c) Tack Coat (RC2):

i) The material (which

shall be primarily approved) shall be applied at the rate of 0.3 to 0.6 lit/ m²

at the temperature not exceeding 54°C above the binder and at where there is a

joint with existing asphalt surface.

ii) The surface shall be

cured for the period as per manufacturer’s recommendations until a tacky

surface is visible.

d) Wearing Course (WBC):

i) The hot asphalt mix

shall be spread over the cured surface of tack coat by automatic asphalt paver

to the required profile and thickness.

ii) The mix shall be

compacted as soon as possible after spreading the material. Tandem roller shall

follow the laying operation to carry out breakdown rolling up to a temperature

of 110°C- 120°C.

Self-propelled rollers

and Tandem rollers shall follow the breakdown rolling and sufficient passes

shall be made to achieve the required compaction.

Rolling shall start from

the sides and proceed toward the center. Each trip of the roller shall overlap

the previous trip by at least 30 cm.

Roller wheels shall be

kept moistened. The roller shall be capable of reversing without backlash and

shall be free from worn parts. Heavy tandem roller (CC-41) shall be used to

complete all rolling including elimination of waves caused by the lighter

rollers Full compaction shall be obtained before the asphalt temperature

reaches 80°C. Compaction shall be in accordance with specification of

relevant standard.

iii) Traffic shall not

be allowed on this layer until it is properly cooled, a minimum period of 12

hours shall be considered after the completion of the rolling.

iv) The test holes shall

me made good with hot asphalt mix and compacted using Marshal Hammer.

Inspection

and Testing:

Testing shall be

conducted by Company’s 3rd party site laboratory.

Relevant QC records shall be raised by Civil

Construction Contractor’s QC Engineer. Also tests shall be carried out as per

the Field Quality Control Plan (FQCP) of Asphalt Work.

Author: Eng. Muhammad Arif (Dar Al Handasah) Saudi Arabia

Comments

Post a Comment